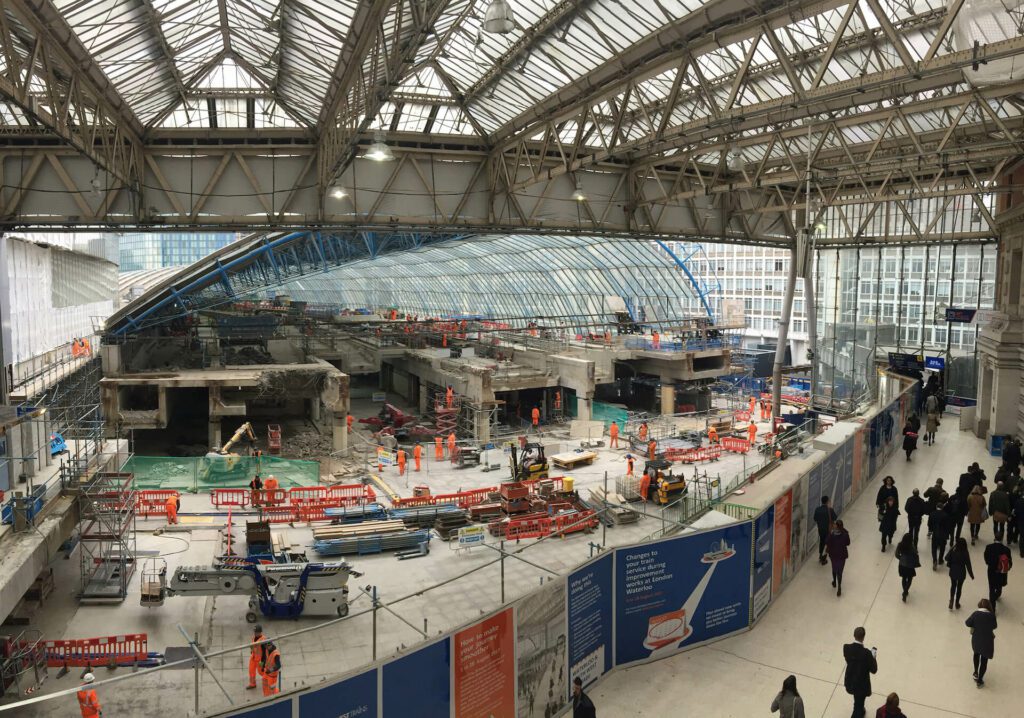

Collaborative approach using engineering solutions to enable safe deconstruction at Waterloo International.

Colemans used all of our project engineering experience to deliver a complex project within some of the most challenging site restrictions we have ever encountered, as part of the £600million regeneration of Waterloo International Rail Terminal.

Our multi-disciplinary team at Waterloo deconstructed and removed 2,000 tonnes of concrete from immediately above the London Underground and adjacent to one of the busiest Network Rail infrastructures in London, with capacity for 500,000 passengers during peak times.

The scope of works Included internal structural alterations, temporary works design, service strip out and waste disposal – all made possible by the experience and specialist skills of our in-house engineering team.

All activities at Waterloo progressed only once Colemans had produced temporary works design packages and structural checks to GRIP 6 drawings – both for temporary structures and when operating from floors incapable of withstanding the weight of plant and arisings.

These structural modifications, including the removal of reinforced concrete slabs, beams, ramps and columns, were required to make the old Eurostar Terminal (including platforms and track beds) operational and enable the station to accommodate 20 trains per hour. A whole new station will emerge from the old terminal, including a large retail area underneath the live platforms.

Our engineering team designed a series of specialist temporary works trusses to support every conceivable length and weight of concrete beam. These trusses were positioned to support the beams as The Colemans team used diamond cutting techniques and Brokks to separate them from the structure.

We also developed innovative design of the temporary structure to tension the Waterloo International Terminal main structure. This supported the structure throughout demolition activities, including when it was weakened due to the removal of structural concrete elements that provided the strength to the roof shear forces.

Colemans used the most advanced deconstruction and demolition methods available, using remote operated plant to progress safely with our works. This included using non- percussive methods, using mitigation controls to reduce noise to a minimum and not imposing any additional dust or vibration into the existing structure or immediate surroundings.

Overall, this was an extremely challenging project, with a number of variables to be considered around site restrictions, temporary works design, noise and dust.

On many areas of the project, the team worked to strict noise restrictions as we were working within close proximity of the heart of Westminster with the London Eye, Houses of Parliament and Big Ben.

Rarely are demolition projects subjected to such challenging restrictions, but we delivered the project successfully thanks to a continued focus on innovation and our ethos of ‘safety by design’.

Colemans’ Project Engineers attended regular internal forums which explored techniques to remove potential hazards during the design phase to make the construction stage safer.

Putting safety and wellbeing first, we swiftly implemented our innovative hazard spotting and reporting app onsite, HazzApp.

HazzApp delivered a tech solution that allowed us to remove an outdated paper procedure and replace with an engaging, easy to use platform to report hazards on site and close out actions in a timely manner – all whilst providing statistics for the business to track trends.

Colemans’ performance at Waterloo was so successful that we set the standard in site set-up for future site contractors, who subsequently followed our lead by incorporating our ideas and best practices into their own working environments.